Wiring harness Termination and connection

Publish:

2025-05-27 18:08

Source:

Wiring harnessand cable assemblies are essential components of many electrical systems. One critical aspect of wire harness and cable assembly design is the selection of the right connector and terminal types.

Types of connectors:

1.Circular connector

Circular connectors are a popular choice for many applications because they are easy to use and provide a secure connection. In harsh environments, such as the military and aerospace industries, these components are a good choice. Circular connectors come in a variety of sizes and configurations, and different numbers of contacts, contact arrangements and locking mechanisms can be selected.

2.Rectangular connector

Most of the connectors from manufacturers such as JST, MOLEX and Tyco that we often use are rectangular connectors. Rectangular connectors are another popular choice for many applications. In automotive and industrial applications, they are easy to use and provide secure connections. Rectangular connectors come in various sizes and configurations, allowing for the selection of different numbers of contacts, contact arrangements, and locking mechanisms.

3.Coaxial connector

Coaxial connectors are highly suitable for applications that require high-frequency signals, such as the telecommunications and aerospace industries. They maintain the integrity of the signal by providing consistent impedance between the source and the load. Coaxial connectors come in a variety of sizes and configurations, and different impedance values, contact arrangements and locking mechanisms can be selected.

Types of terminals:

1. Crimp terminals are a popular choice for many applications because they are easy to use and provide a secure connection. They are very prominent in automotive and industrial applications. Crimping terminals come in a variety of sizes and configurations. They also have to choose different wire gauges, insulation types and termination methods.

Crimp terminals are a popular choice for many applications because they are easy to use and provide a secure connection. They are very prominent in automotive and industrial applications. Crimping terminals come in a variety of sizes and configurations. They also have to choose different wire gauges, insulation types and termination methods.

2.Soldering(DIP) terminal

Soldering terminals are very common in applications that require safe and high-quality connections. Reliability is of vital importance in the aerospace and military industries. Solder terminals come in a variety of sizes and configurations, allowing for the selection of different wire gauges, insulation types, and termination methods.

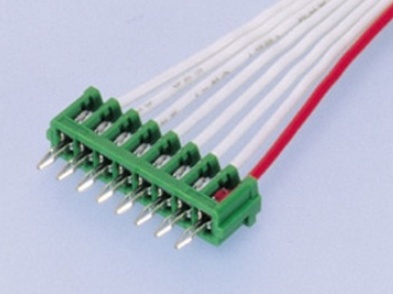

3.Insulated displacement Terminal (IDTS Terminal )

3.Insulated displacement Terminal (IDTS Terminal )

idt is a type of terminal that allows wires to be inserted into terminals without the need to remove insulation. idt is very common in applications where wires must be terminated quickly and conveniently. They are very common in automotive and industrial applications. idt comes in a variety of sizes and configurations, allowing for the selection of different wire gauges, insulation types, and termination methods.

In conclusion, choosing the correct connectors and terminals for wire harnesses and cable assemblies is crucial for ensuring the reliability of the assemblies and meeting application requirements. Circular and rectangular connectors are popular choices for many applications, while coaxial connectors are used for high-frequency signals. Crimping terminals, solder terminals and IDT terminals are usually used. Depending on the specific requirements of the application, each type of terminal has its own advantages. By choosing the right connector and terminal type, you can ensure that your wiring harnesses and cable assemblies are reliable and meet your application requirements.

Prev:

Related News

Exploring the Benefits of Using a High-Speed Micro USB Cable

Exploring the Benefits of Using a High-Speed Micro USB Cable Table of Contents Introduction to High-Speed Micro USB Cables Understanding Micro USB Technology Benefits of High-Speed Micro USB Cables Enhanced Charging Efficiency Fast Data Transfer Compatibility and Convenience How to Choose the Best Micro USB

May 31,2025

Understanding Motor Control Cables: A Guide for Electrical Professionals

Motor control cables are specifically designed to connect electrical motors to control systems, ensuring seamless communication and operational efficiency. These cables are engineered to withstand the demanding environments typically associated with motor control applications, which often include exposure to heat, moisture, and mechanical stress. A key characteristic of motor control cables is the

May 28,2025

Wiring harness Termination and connection

Wiring harness and cable assemblies are essential components of many electrical systems. One critical aspect of wire harness and cable assembly design is the selection of the right connector and terminal types.

May 27,2025

Wiring harness and cable assembly sleeving bushings

Cable Sleeve is a device used for wrapping, protecting and managing cables and wiring harness. Its main functions include physical protection of the wire harness, anti-wear and high-temperature protection. Organize loose cables into bundles to prevent messy entanglement of cable harnesses and improve the neatness of the wiring. Block the interference of external EMI to the cable, prevent leakage or short circuit of the cable harness assembly through insulating materials, and enhance safety by being flame-retardant and fireproof.

May 27,2025

Manufacturing Challenges of Medical Cable Assemblies and Wire Harness

Medical cable assemblies and wire harness assemblies are of vital importance in the field of medical equipment and are key links for the functional and reliable connection of many devices. These dedicated cable assemblies and wire harness assemblies are crucial for transmitting power and data, and are widely used in diagnostic imaging systems such as MRI and CT scanners, as well as patient monitoring devices such as electrocardiograms and electroencephalograms.

May 26,2025